Collaborative design & engineering that improves performance, cuts costs, and optimizes parts for precision metal fabrication.

Let’s build smarter.

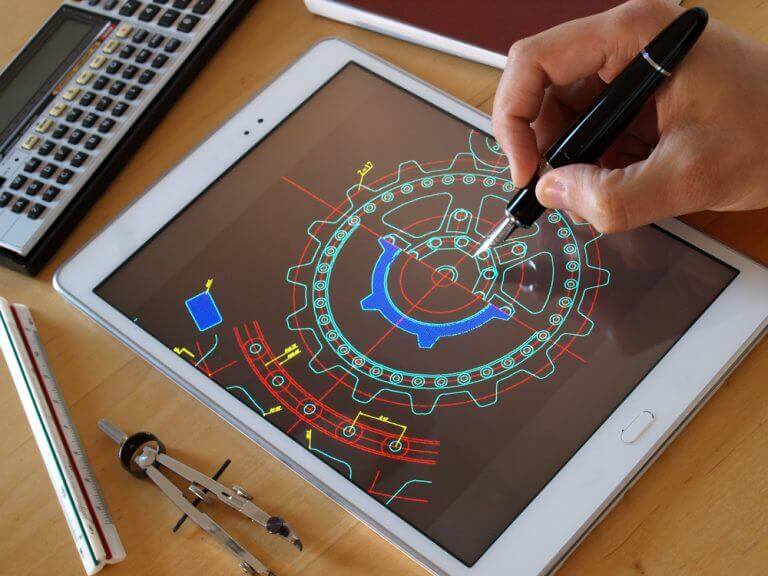

Design and engineering are a critical element of Starflex Fabrication’s full-service capabilities. Our engineers provide hands-on support, helping you develop, refine, and improve your component designs for manufacturability, efficiency, and optimal performance. Our collaborative, service-driven approach to design and engineering is integral to our core commitment to finding innovative solutions to the challenges our clients face.

Our in-house engineers come from the fabrication floor, bringing hands-on experience to identify potential production challenges early and optimize your parts for cost-effective fabrication. We offer support across the full development cycle, from prototyping and modeling to final revisions and production handoff.

Our fabrication design support includes:

We combine expert craftsmanship with state-of-the-art software to ensure every design we touch is production-ready. Our engineering team utilizes SolidWorks for interactive 3D modeling, enabling detailed visualization of parts and simulation of their movement. That data feeds directly into our fabrication equipment for seamless integration and consistent results.

Key tools in our process include:

Used for programming our Amada laser and Amada press brake systems. It streamlines toolpath planning, material nesting, and press brake bending sequences for optimal accuracy and reduced waste.

Enables detailed assemblies, real-world movement testing, and fitment validation before fabrication begins.

Every design undergoes the same attention to detail and quality control that drives our fabrication shop. As an ISO 9001:2015 certified company, we follow structured design review and revision protocols to maintain accuracy and compliance. We also support regulated industries through specialized certifications:

For food and beverage equipment design

For defense and military fabrication projects

Our design & engineering team works hand-in-hand with fabrication, finishing, and assembly to streamline the full production process. By aligning design decisions with production realities, we help shorten lead times, reduce costs, and avoid unnecessary rework. The result: better parts, fewer delays, and faster delivery to your door.

Whether you need full-service support or a second set of eyes on your design, Starflex Fabrication is ready to help. From fabrication design and modeling to final production, we bring practical insight, technical skill, and responsive service to every project.

Let’s talk about how our design & engineering services can support your next job.